All Categories

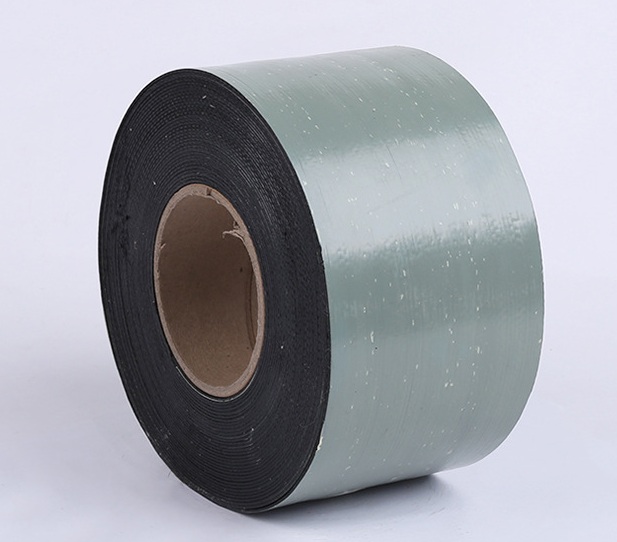

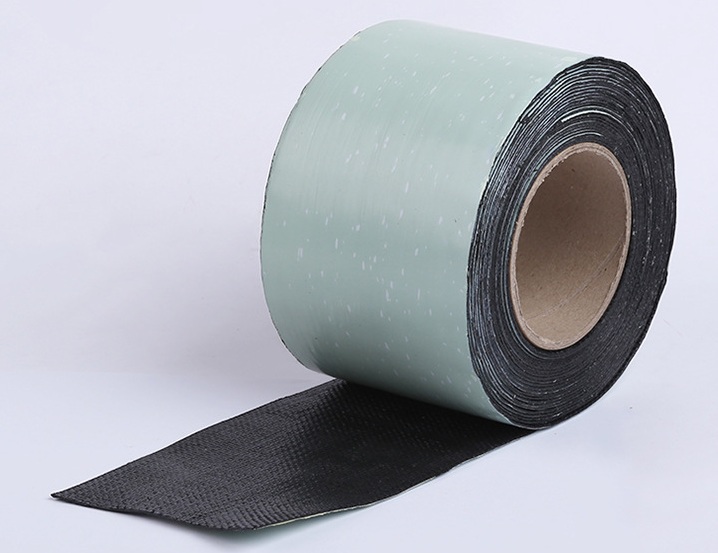

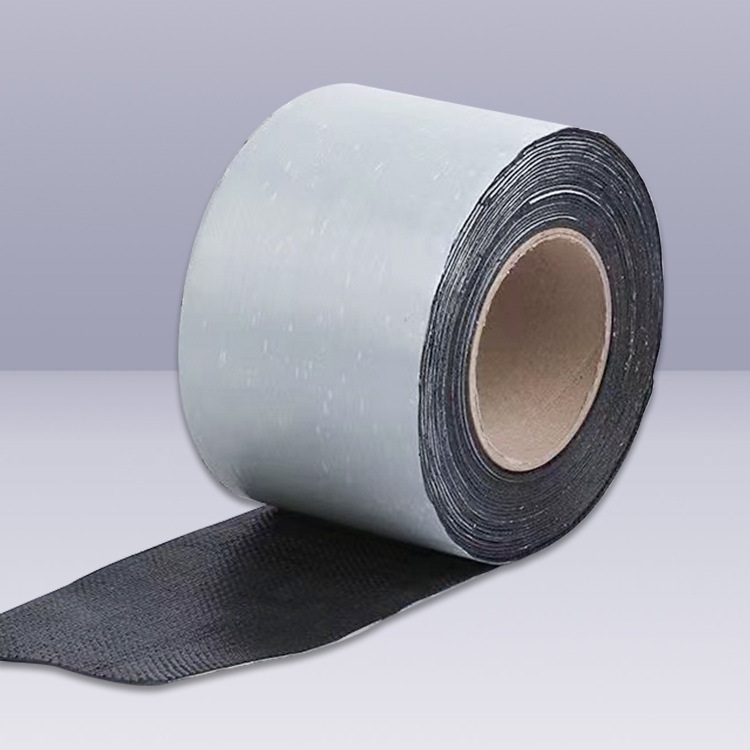

Pipeline anti-corrosion tape is also called polypropylene reinforced fiber anti-corrosion tape (foreign brand called RD-6 tape), referred to as: polypropylene anti-corrosion tape or reinforced fiber anti-corrosion tape, a pollution-free, non-hazardous and environmentally friendly pipeline anti-corrosion tape. The unique modified polypropylene mesh reinforced woven fiber geotextile is used as the base material, and the high-viscosity butyl rubber modified asphalt is used as the adhesive layer. It has been successfully trial-produced through thermal compounding technology, and then covered with a layer of anti-adhesive isolation film. Used with primer during construction. For more than ten years, it has been widely used in the external corrosion protection of steel pipelines and buried steel storage tanks in petroleum, natural gas, gas, chemical and urban construction.

Details of Pipeline Anti-corrosion Tape

Material: Polypropylene fiber

Adhesive: Butyl rubber modified asphalt

Product viscosity: High viscosity

Color: Black

Thickness: 1.15mm

Width: 50mm-300mm

Length: 15m-120m

Temperature resistance: -34~+75℃

Features:

Anti-bending suit/Wear resistant/Impact resistance/Aging resistance/Preservative/Electric shock resistance

Features of Pipeline Anti-corrosion Tape

Technical data of Pipeline Anti-corrosion Tape

| Total thickness (mm) | 1 | 1.1 | 1.2 | 1.4 | 1.5 | 1.65 | 1.8 | |

| Adhesive thickness (mm) | 0.7 | 0.8 | 0.9 | 1.05 | 0.95 | 1.1 | 1.2 | |

| Substrate thickness (mm) | 0.3±0.05 | 0.6±0.05 | ||||||

| Tensile Strength | ≥65Mpa | |||||||

|

Strength of primed steel |

23°C | >15N/cm | ||||||

| 75°C | ||||||||

| Peel strength to back material | ≥28N/cm | |||||||

| Cathodic stripping | 8mm | |||||||

| Water absorption | <0.3% | |||||||

| Water vapor transmission rate | 0.35 g/m²·24h | |||||||

| Volume resistivity | ≥1.5×10¹²Ω·m | |||||||

| Electric strength | ≥35Mv/m | |||||||

| Impact resistance | 23N·m | |||||||

| Heat resistant | -34~+85°C | |||||||

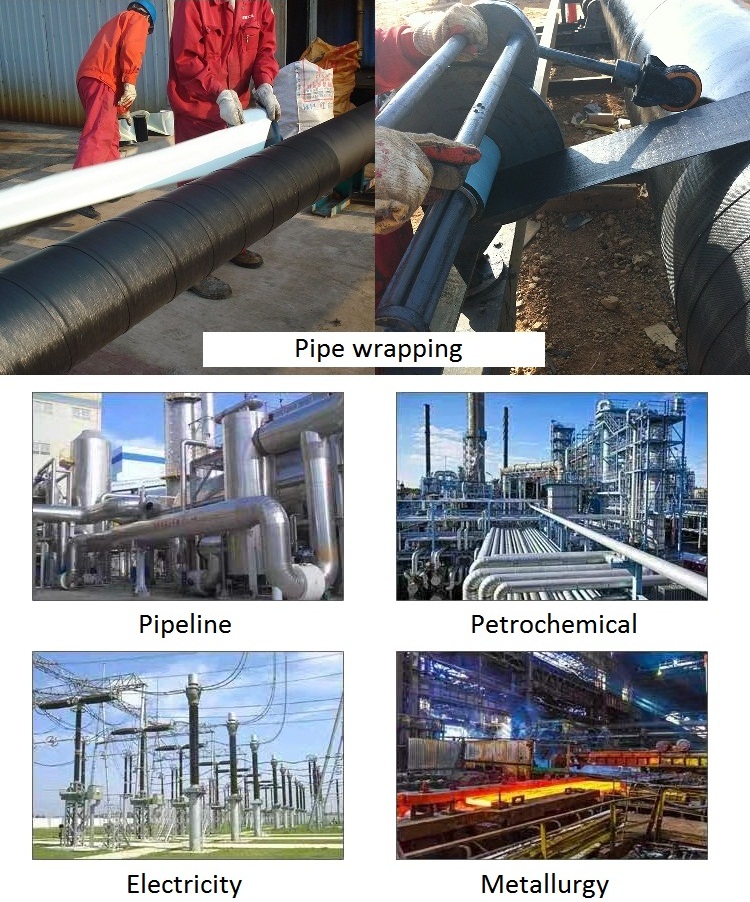

Applications of Pipeline Anti-corrosion Tape

Oil pipeline, natural gas pipeline, pipeline anti-corrosion layer repair.

Instructions and Transport Storage

Instructions:

1. Surface treatment for anti-corrosion protection: rust removal, welding slag removal, burr removal, oil stain removal and sundries, and keep it clean and dry. Meet the requirements of GB/T 8923, the manual derusting should reach St3 level, and the mechanical derusting should reach Sa2.5 level.

2. Applying primer: Keep away from fire sources when using, stir evenly and apply evenly with a clean brush, roller brush or other mechanical methods.

3. The primer can be wrapped after 5-10 minutes of surface drying. During the construction process, it is necessary to increase the balance tension of the tape so that it can be closely attached to the working surface and achieve the effect of wrapping without gaps and wrinkles.

4. Use the matching primer P27 produced.

5. Construction temperature: -5°C ~ +50°C; open-air construction is prohibited in rainy, snowy, foggy days, wind humidity > 85%, and in sandy environments.

Transport Storage:

1. Anti-exposure, anti-rain, anti-freeze and heat preservation, prevent crushing and deformation.

2. When subjected to severe freezing below -5°C during transportation or storage, it needs to be stored at around 20°C for 48 hours before use.

3. It should be stored in a warehouse with a relative humidity of <75% and a temperature of 5-30°C, and away from heat sources and open flames.

4. The shelf life is 12 months.

We ask the service staff to always think about the customers, solve the problems of the equipment in time, and make sure that the interests of customers are above everything else.

Share

Share