All Categories

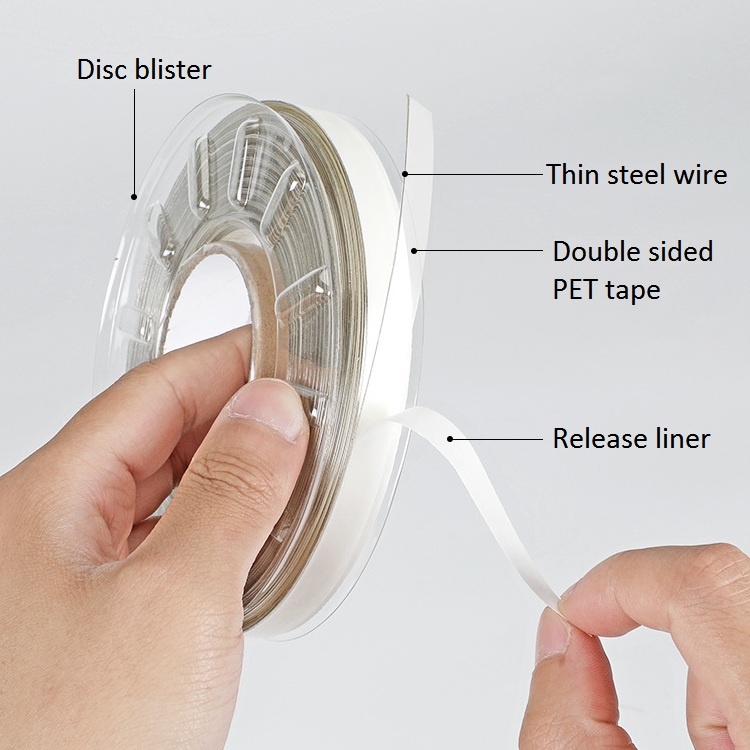

The Edge Cutting Tape is a special double-sided PET tape with embedded fine steel wire, designed for trimming and finishing coating edges, making it ideal for achieving clean, precise lines in industrial and automotive applications. Its primary use is in refining the edges of car doors, hoods, trunks, pickup trucks, and cargo compartments, providing a professional finish without damaging the underlying surface.This tape is manufactured by sandwiching a fine steel wire between PET double-sided tape, which gives it high bonding strength, excellent adhesion, and temperature resistance. The embedded wire acts as a precise cutting filament, allowing the tape to cut through strong coatings from the bottom up. After applying the coating, the wire filament is pulled upwards from beneath the new coating, producing a clean, perfect edge and enabling easy removal of the masking tape without leaving marks or disturbing adhesion.

Features of Wire Trim Edge Cutting Tape

High-strength wire-reinforced PET tape: Provides excellent cutting performance and durability.

Ideal for automotive applications: Perfect for car doors, hoods, trunks, pickup trucks, and cargo compartments.

Excellent adhesion: Strong bonding ensures stable placement during coating and edge trimming.

Conforms to complex surfaces: Easily adapts to compound curves and tight corners.

Temperature resistant: Maintains performance under high and low temperature conditions.

Clean edge trimming: Achieves perfect edges without damaging surfaces or disturbing new coatings.

Easy removal: Wire filament lifts smoothly, simplifying tape and masking material removal

Technical Data of Wire Trim Edge Cutting Tape

| Adhesive | Solvent acrylic adhesive |

| Carrier | PET + stainless steel |

| Adhesive side | Double Sided |

| Color | Transparent |

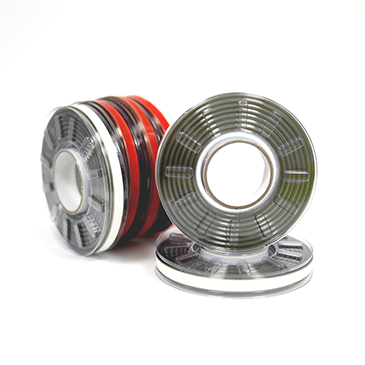

| Size | 6mm/8mm/10mm*30m or customize |

| Thickness | 0.26mm |

| Packing | Each roll with a blister |

| Peel adhesion | >0.6KG/IN |

| Initial tack | <10CM |

| Holding power | ≥24hrs |

| Temperature | 21℃–38℃ |

| Strength tensile | 2200N |

| Stickiness | Medium adhesion |

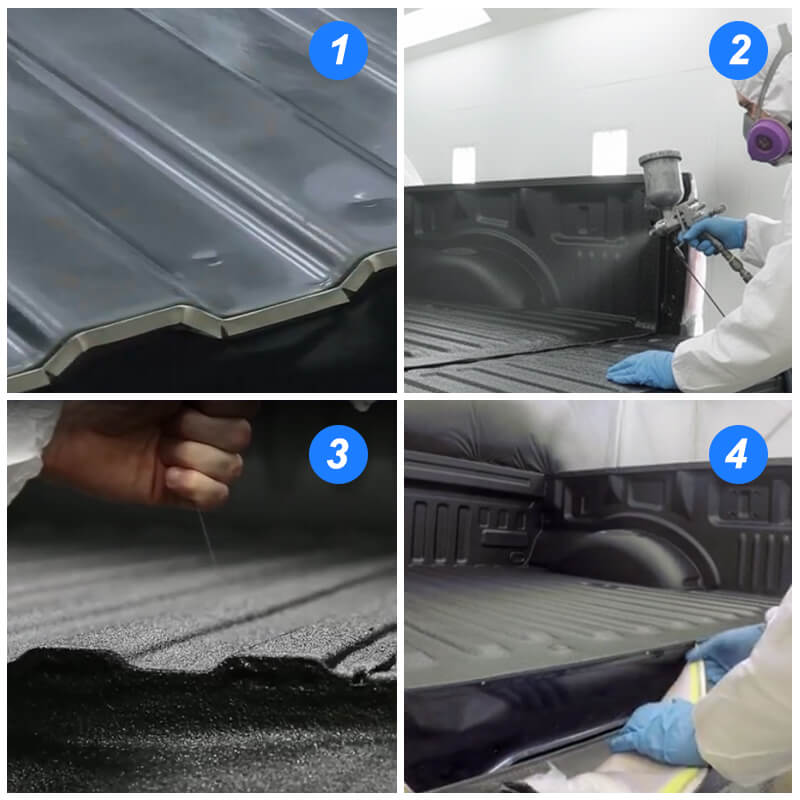

How to use

1. Clean the Surface: Ensure the area is dry, free of dust and oil.

2. Apply the Tape: Place the edge cutting tape along the coating edge, making sure the embedded steel

wire contacts the surface.

3. Perform Coating: Apply paint or coating over the taped edge.

4. Pull the Wire Filament: After coating, gently pull the embedded steel wire from beneath the new layer

to create a precise, clean edge.

5. Remove the Tape: Peel off the tape easily without leaving residue or damaging the surface.

6. Inspect Finish: Ensure a neat, professional edge for a perfect coating result.

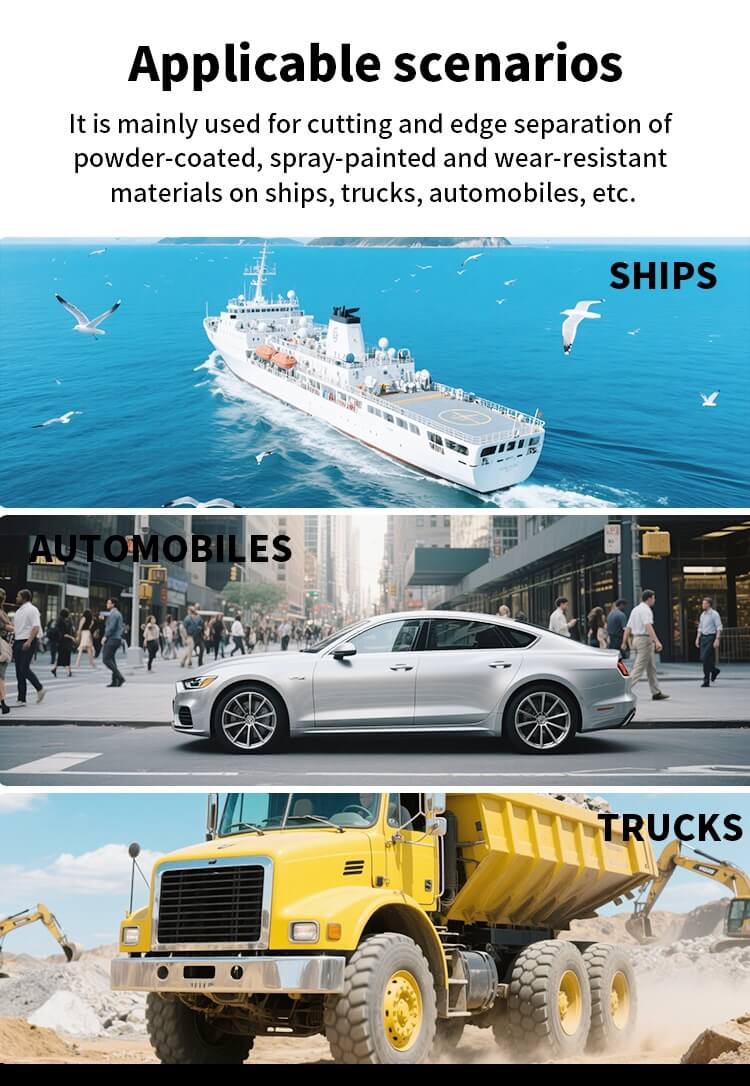

Applications of Wire Trim Edge Cutting Tape

The Edge Cutting Tape is mainly used for precise edge trimming in coating and painting applications, especially in the automotive industry. It is ideal for creating clean, sharp lines on car doors, hoods, trunks, pickup trucks, and cargo compartments.

We ask the service staff to always think about the customers, solve the problems of the equipment in time, and make sure that the interests of customers are above everything else.

Share

Share